WIND POWER

THE DELOM ADVANTAGE

Due to its many years of experience with electromechanical and rotating equipment, and given its mission, the company decided to establish the Wajax | Delom Wind Division. As wind generator specialists, Wind Division teams offer wind generator exchange plans, as well as a full range of services, in-shop or up-tower, to maintain, repair, and improve equipment, and to provide spare parts.

Wind Division teams carry out repairs and overhaul for all types of wind generator technology, whether for preventive or predictive maintenance, an end-of-warranty inspection, reverse engineering, or a full rewinding of the rotor and/or stator. We also provide our clients with reports outlining the root cause of the failure, as well as complete repair reports to provide a 360o vision of their units. Our goal is to reduce to a minimum the wind turbines’ downtime, while optimizing the units for the proper functioning of the wind generators.

Over the years, various types of generators have had failures that seemed redundant due to designs that were not adapted to the extreme weather conditions in northern areas. Wajax | Delom Wind Division therefore established retrofit procedures that can be carried out up-tower or in our workshop that are correcting the shortcomings of those wind generators designs.

The Wajax | Delom Wind Division has developed several innovative repair techniques enabling us to carry out a very large number of specialized electrical and mechanical works up-tower. Our up-tower service teams are multidisciplinary, minimizing the need to remove the generator from the turbine. Wajax | Delom Wind Division also carries an inventory of replacement parts for wind generators, such as brush holders, brushes, bearings, etc.

DELOM AND THE INDUSTRY

The wind power industry is on the rise all over the world. This clean renewable energy is abundantly available in Canada and North America. The technologies related to wind power generators, however, are relatively new compared to other energy sources and Nordic climates poses challenges that cause stress and wear on the structures as well as on the generators and mechanical components.

Removing a generator from the tower to repair it bares significant direct costs as it calls for cranes and specialized operators. The indirect costs, however, are also prohibitive due to a stoppage of production while the unit is being repaired. This is why Wajax | Delom works side by side with its client to develop efficient and durable solutions to reduce and prevent failures and to improve the generators electrical and mechanical stability.

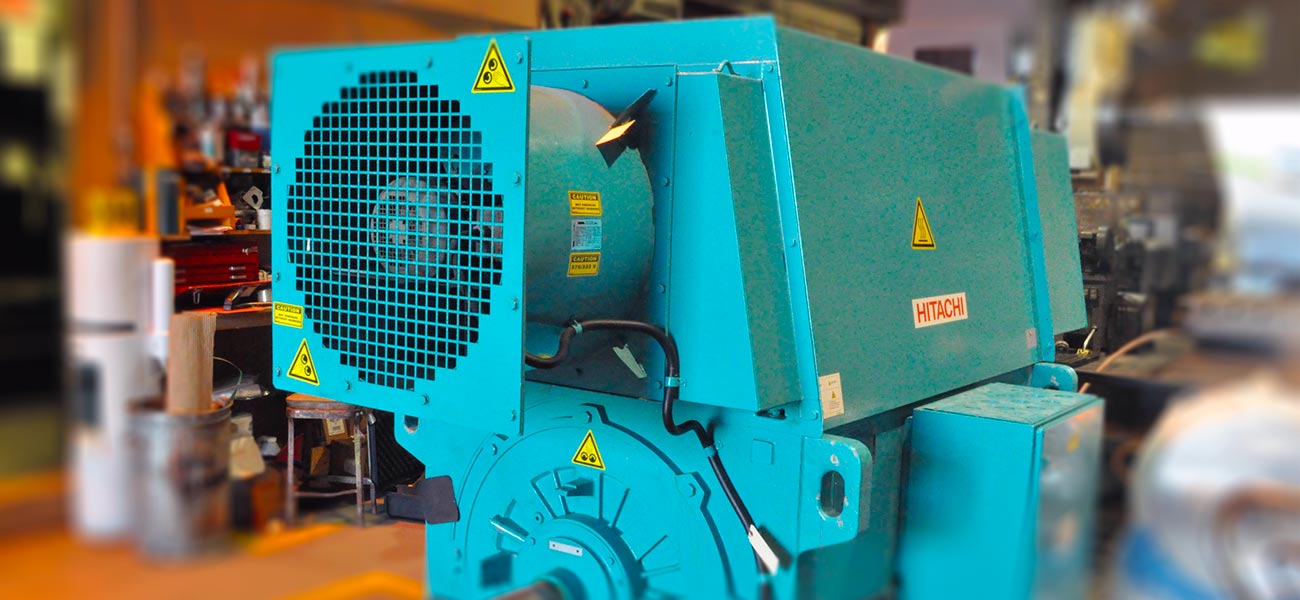

- Hitachi wind generators 1,5 MW/1,6 MW, up to 3 MW and more

- GE wind generators 1,5 MW/1,6 MW, up to 3 MW and more

- ABB wind generators 1,8 MW/660 kW/1,5 MW, up to 3 MW and more

- Weier wind generators 1,8 MW/2,0 MW, up to 3 MW and more

- Winergy wind generators 1,5 MW/2,3 MW,

- Loher wind generators 1,5 MW

- Elin wind generators 750 kW/1,5 MW, up to 3 MW and more

- Leroy Somer wind generators 660 kW/1,5 MW/1,8 MW, up to 3 MW and more

- VEM wind generators 1,5 MW, up to 3 MW and more

- Siemens wind generators 225 kW/2,3 MW, up to 3 MW and more

- Toshiba wind generators 1,5 MW, up to 3 MW and more

- Enercon wind generators up to 3 MW and more

- Indar wind generators up to 3 MW and more

- Canterey wind generators up to 3 MW and more

- Haiphong wind generators up to 3 MW and more

- Wye ring retrofit for Hitachi wind power generator

- Wye ring retrofit for GE wind power generator

- Wye ring retrofit for ABB wind power generator

- Rotor cables retrofit for ABB, GE and Hitachi wind power generators

- Brush/brush holder retrofit and full analysis

- Stator and rotor rewinding

- Coil manufacturing all types and voltages

- B-Stage winding

- VPI impregnation up to 16 ft. in diameter

- Retrofit of connecting cables, wye ring, brush, brush holder and collector rings

- Test in rotation

- Dynamic balancing

- Laser alignment

- Mechanical components overhaul and verification

- Machining

- Bearing seat casing

- Main shaft seat chroming

- Full welding service

- Bearing shaft seat correction

- HVOF

- Thermal spray

- Engineering service for root cause of failure analysis

- Detailed repair report

Electrical :

- Complete electrical troubleshooting (generator)

- Electrical tests on wind turbine generators rotors and stators

- Insulation resistance

- Polarization index (PI)

- Dielectric discharge (DD)

- Hi-Pot test

- Resistance and Impedance test

- Surge test

- Drop test

- Brushes/brush holders and slip ring system maintenance and application analysis

- Failure analysis report

- Intervention report

Mechanical :

- Complete mechanical troubleshooting

- Vibration analysis on wind turbine generators, gearboxes and auxiliary electric motors

- Visual and borescope inspection

- Generator and gearbox alignment

- Generator dynamic balance

- Bearing replacement and failure analysis on generators and gearboxes

- Ultrasonic bearing lubrication

- Oil and lubricant analysis on generators and gearboxes

- High speed and intermediate shafts replacement

- Post-installation verifications including vibration analysis and thermography

- Failure analysis report

- Intervention report

OTHER WIND POWER COMPONENTS SPECIALIZED SERVICES

- Pitch electric motor winding and refurbishing

- Fan electric motor winding and refurbishing

- Yaw speed reducer refurbishing

- Heat exchanger refurbishing

- Winding and transformer refurbishing

- Winding and inductance refurbishing

- Resister bank refurbishing

- HVOF main shafts refurbishing

- Gear casing inspection

- Generators in inventory for exchange plans

- Wind generator power brushes and ground brushes

- Wind generatorbBrush holders

- Wind generators slip rings

- Pitch motor brushes

- Yaw gears

- All bearing types

- Auxiliary motors

- All parts related to wind generators

Two-day training program including:

Electrical:

- The wind turbine generator and its components

- Generator electrical Troubleshooting

- All electrical tests to ground & between turns and analysis

- Borescope-assisted visual inspection

- Hands-on activities on real generators

- Case studies and skill certificate

Mechanical:

- Generator mechanical troubleshooting

- Methods of mechanical inspection

- Bearing condition inspection

- Lubrication and its impact on vibration

- Introduction to vibration analysis

- Hands-on activities on real generators

- Case studies and skill certificate

specialized workshops